I was able to get some time in the shop to finish the apple press and some other projects that were in pieces on my work bench. Knowing everything was going to sit in pieces all summer was eating at me so I started about 4:30am and worked till about 6pm and knocked out everything on the list. The apple press was only part of what I worked on that day. Now I have a perfectly clean work bench and I can go in good conscience to the lake and have fun with the kids.

Pictured above is a conversion kit from Swag Offroad mounted to my Porter-Cable portaband bandsaw. This allows me to use my portable bandsaw as a bench mount saw. I have a big cut-off saw that I never use as the portaband does everything so well I always grab it first. The only thing lacking was a mounted option. I’ve had this kit in the box most of the winter. Doing the final work on the apple press knives caused me to finally pull it out and put it to work. It worked perfectly.

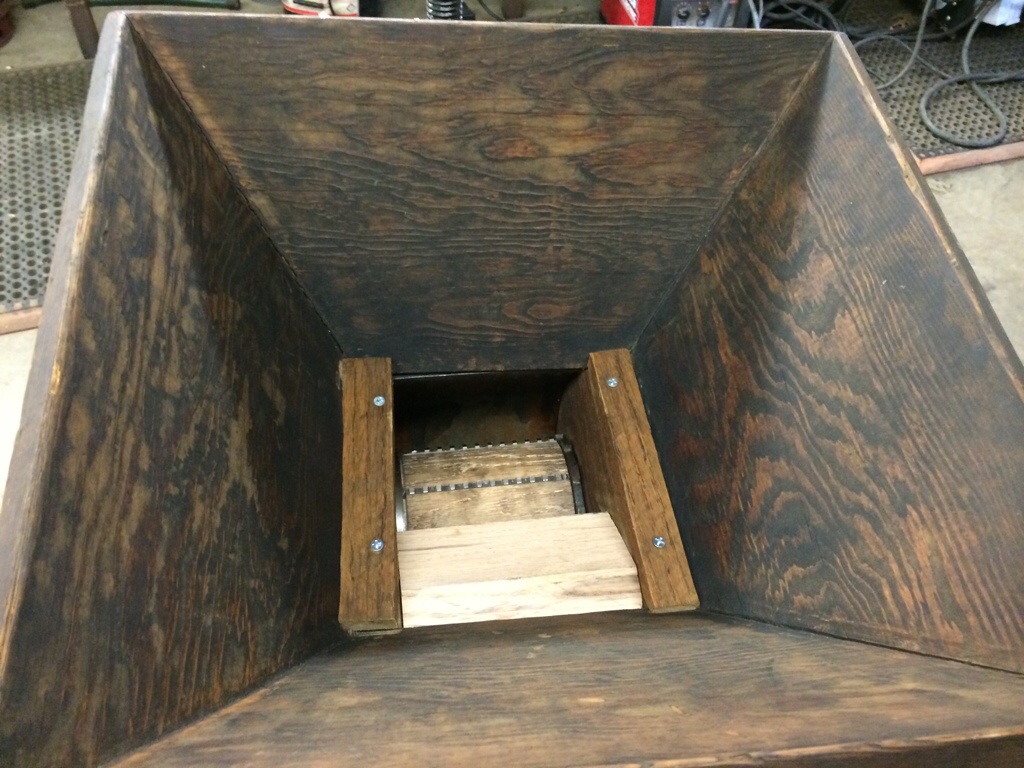

Sawing the slots in the drum was tricky. They had to be at the correct place on the drum so it stays balanced. They also had to fit closely to hold the knives in place. Plus they had to be at the correct depth, straight, etc. All that precision required a 15 minute jig made of scrap lumber lying around the shop. Here you can see the drum marked up for where each slot will be. A hold down vice grip was borrowed from the drill press and we had all the slots cut in another 15 minutes.

You can see the other holes marked on the drum. This was Miguel’s idea I tried to describe in a previous post. The idea was to have a positive retention system for the knives utilizing this hole. The idea worked, but it didn’t hold the knives in place well enough to be the primary retention system and the work to make the knives in this shape was too much to justify the time and tooling.

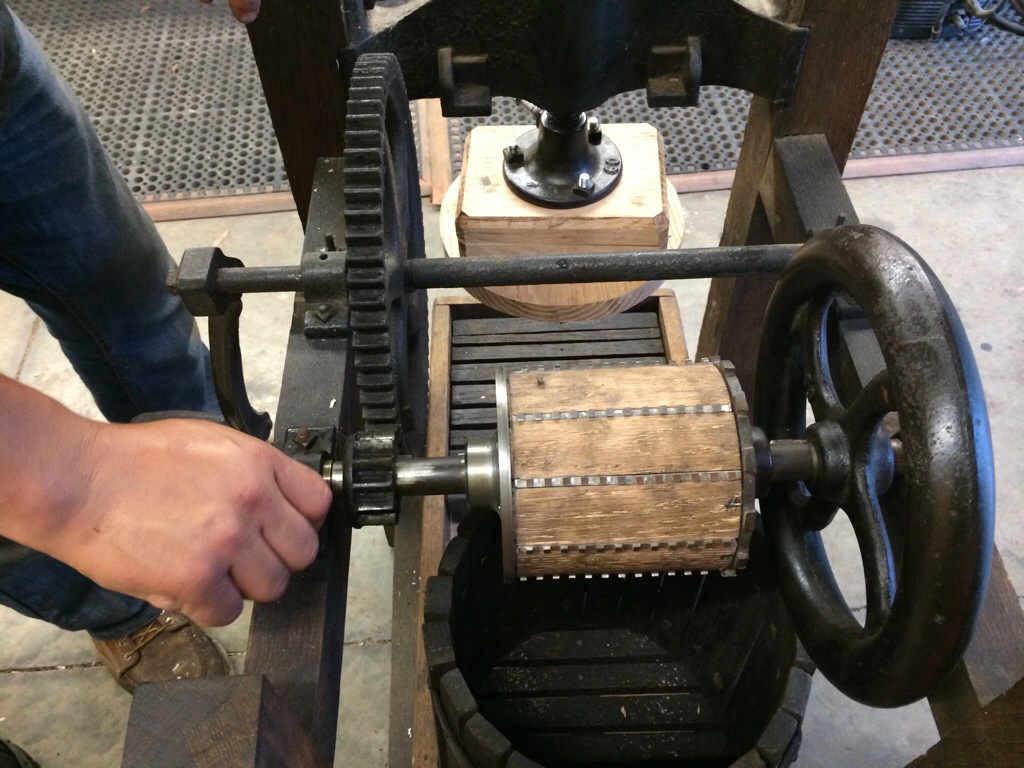

What all this work was for. A new drum, made from laminated red oak which should last past my lifetime and maybe my kids. New knives made from 304 stainless steel, twice as thick as the previous knives. Again, these should last well beyond my need.

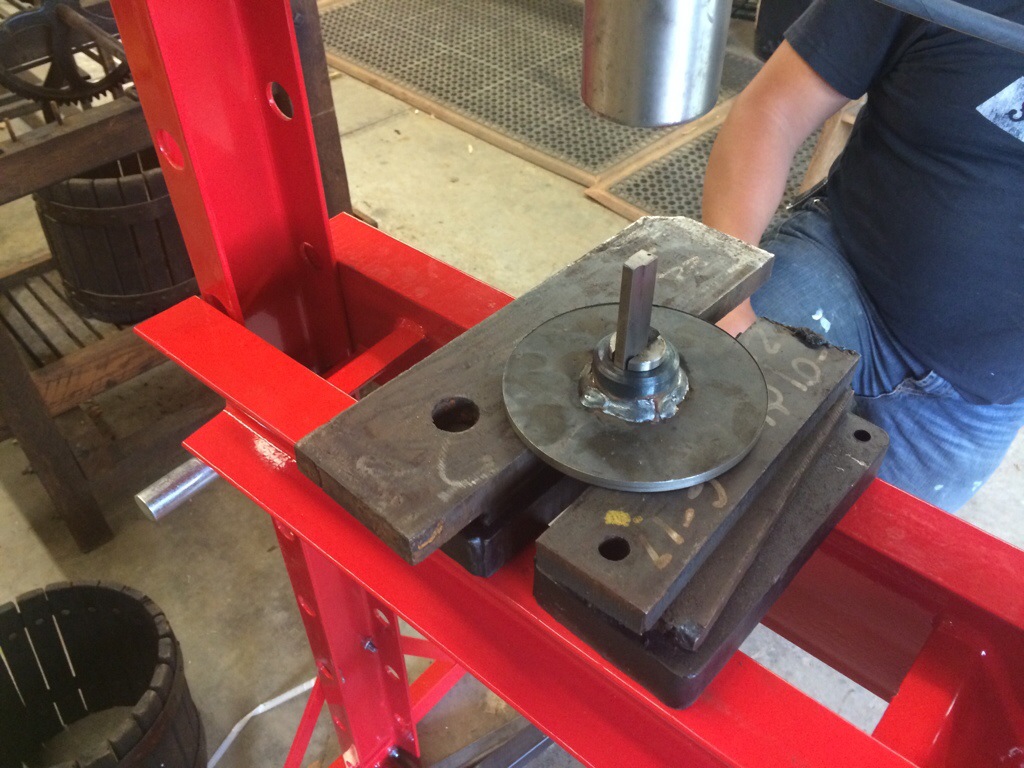

We had to use our press again, this time to put things back together. The drive gear went on my hand but the macerator and the flywheel both had to be pressed back onto the shaft. I didn’t clean the shaft before putting it back together because the marks where everything was seated originally were still plain. This made it easy to put everything back together.

It was interesting putting it back together at this point. When we gave it a test run the drive gear sloughed off a bunch of gunk because the drive teeth were properly engaging for the first time in many years. We’re back to metal on metal the way it was intended.

And here it is. Six posts and many man hours later, all finished and waiting on apples. I told Miguel I think we used every tool in the shop on this restoration. We even ended up using the new (to us, very used otherwise) Piranha ironworker to finish making the knives. Now we just need some apples!

It appears that everything works correctly and all this thing needs is a few bushels of apples. Before we use it, everything will get a good bath and a wash down with bleach. No sense in being too fussy at this point since it’s just going to sit in the barn till fall apple season anyway.