I mentioned a few weeks ago that we had a power outage at the barn. The culprit for this outage is a tree that has been dying for a few years now and is now officially dead.

To make it more complicated, this tree is inside of the pig paddock, with fencing on two sides. The power for the barn is on the third side, and trees are all around it. It’s also leaning towards the power line and the barn and behind it is another tree that is in the way.

First, I had Duke Energy come out and disconnect power from the barn and get the cable out of the way. That was if we dropped anything the wrong direction, we wouldn’t accidentally lose power and tear something up.

By the time the above picture was taken we’d already dropped the small tree behind it. It was only 25″ across at the butt. You know, the kind of tree that would all by itself be a major issue you’d need a tree service for. That one I dropped without even waiting for Miguel to finish feeding to help me. It paled in comparison the dead tree.

Now onto the scary tree. The real killer in tree work is falling limbs. A dead tree is ripe to drop a limb on you and kill you so it’s extra concerning to be working on a tree that is dead.

Since the tree was in the pig paddock and next to the fence, we couldn’t use a tractor to push the tree where we wanted it to go. We brought in our digger derrick with its massive hydraulic winch.

We rigged a chain to a tree about 25 yards away and put a pulley on that chain. Then we routed the winch cable through the pulley and back uphill to attach to the dead tree. This allowed us to pull the tree in the direction it needed to go, and more importantly against the direction it wanted to go. Remember it was leaning towards the barn.

Once the tree and winch setup were rigged (after Miguel rightly pointed out I should have the cable higher on the tree), it was time to cut the felling notch in the front of the tree.

It’s actually been a little while since I’ve done any chainsaw work, so it was fun to get in here and do some cutting.

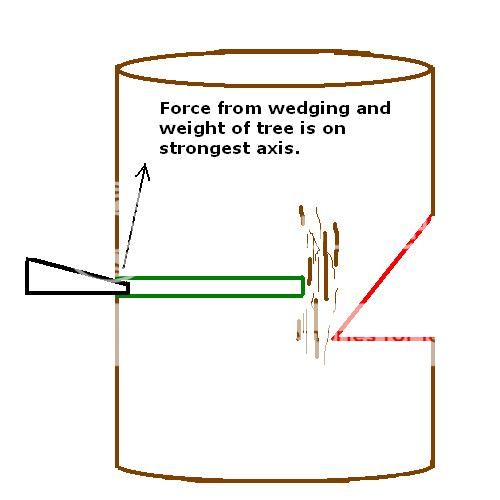

Once the notch was in I checked everything again and then moved onto the back cut. Once the cut was partially in, I inserted a couple of wedges so that the tree would not try to move the wrong direction and then finished my back cut.

We pulled on the tree a bit with the winch and it wouldn’t move. I’d left plenty of hinge wood so I went back in and cut a bit more. This is the scariest part of working on the tree. It’s too strong to fall, but not strong enough to stay up. You are right at the base of the tree with all kinds of forces at play. I cut a bit more, weakening the hinge, then got back out of there and we pulled with the winch again. Again the tree wouldn’t move.

Finally I remembered the winch was hydraulic, not electric so it would have a little more power if we revved the engine. Miguel gave the truck the gas and the tree finally moved.

After we had everything on the ground, we went back to work as normal. I called Duke Power and they came right out and hooked our power line back up and Miguel and I cleaned up the tools, trucks, etc. Then Miguel and the boys moved the pigs back out of the barn and into the paddock where they were excited to see this big addition to their home.

Just another day on the farm.